-

About us

Business Areas

-

INTEKPLUS has surface inspection solutions in various fields, including semiconductor packages, semiconductor substrates, displays, and secondary battery industries, based on vision machine technology.

We will expand businesses of automated surface inspection with constant challenges and provide visual inspection solutions to implement our customers' advanced technology more perfectly and safely.

Business Unit 1

- Semiconductor Back-End Inspection Division

- Advanced packaging technology is becoming the most effective and essential means for improving semiconductor performance in the post Moore's Law era. Inspection equipment with the high-performance vision technology of INTEKPLUS provides the most suitable surface inspection solution in the era of heterogeneous integration.

-

- Improving Semiconductor Reliability through Innovative Technology

- INTEKPLUS ' 3D measurement, 2D inspection, 6-sided direct inspection, stiching and deep learning technologies lead innovation in the field of semiconductor back-end inspection by providing the fastest and most accurate visual inspection solution.

-

- Various inspection solutions - Semiconductor package, Memory Module, SSD

- INTEKPLUS improves Semiconductor post-processing productivity, yield, and reliability by supplying visual inspection equipment for semiconductor PKG, Memory modules, and SSD semiconductors.

Business Unit 2

- Semiconductor Substrate Inspection Division

- High-performance, high-density semiconductor substrates for HPC (High Performance Computing), artificial intelligence, autonomous vehicles, and server semiconductors are getting bigger and smaller. INTEKPLUS's inspection equipment applied with WSI (White Light Scanning interferometer) technology quickly and accurately inspects bumps and spaces on high-performance, high-density semiconductor substrates.

-

- Large FOV Coherence Scanning Interferometer (LCSI)

- INTEKPLUS's LCSI technology, which is based on WSI (White Light Scanning interferometer) technology, is the optimal inspection solution for the evolving semiconductor substrates for flip-chip.

-

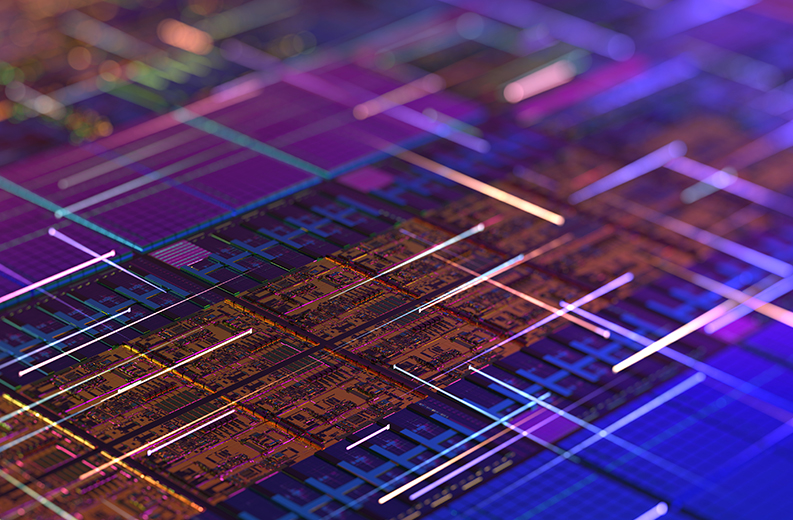

- Technology to further perfect the semiconductor mid-end process

- Major semiconductor substrate companies around the world are choosing INTEKPLUS inspection equipment. INTEKPLUS's inspection solution helps to more perfectly implement the next-generation mid-end process that evolves in the form of PLP and WLP as well as for FC-BGA and FC-CSP.

Business Unit 3

- Display inspection Division

- Displays are evolving into flexible, stretchable, micro-displays and holograms that can be viewed anytime, anywhere without any restrictions on shape. INTEKPLUS's machine vision technology provides a new process for realizing high-performance displays and an optimal inspection solution that makes new functions more perfect.

-

- SP2S and Auto Focusing technology applied

- SP2S technology and Auto Focusing technology utilizing INTEKPLUS's unique 3D Surface Profiling technology quickly and accurately inspects defects that may occur during the manufacturing process of LCD panels and Flexible Oled Cells.

-

- Improving productivity and process efficiency through machine vision

- INTEKPLUS is contributing to the improvement of productivity and efficiency in various processes, from the entire process of displays and displays in the LCD and OLED fields to the module assembly process.

- Battery inspection field for electric vehicles

- Batteries for electric vehicles are making various attempts for fast charging and long-distance driving. INTEKPLUS's vision technology adds stability in the eco-friendly era by removing the threat to safety that may occur in the manufacturing process.

-

- 2D/3D Vision Inspection + Deep Learning

- By adding deep learning technology to INTEKPLUS's 2D/3D vision inspection technology, we provide an inspection solution that can accurately and quickly inspect even atypical defects.

-

- Providing various inspection solutions

- We provide a variety of inspection solutions from compact optical modules that can be installed in process facilities to integrated equipment that inspects the quality and appearance of finished battery cells.

Technology Commercialization Group.

- Smart Factory &

Vision Module - We have launched a 'Smart Factory Vision Solution' that can integrate the world's best machine vision technology of INTEKPLUS with various applications. 'Smart Factory Vision Solution' is the best solution needed to build automation systems for various industries.

-

- Technology recognized in the high-tech industry

- INTEKPLUS's machine vision solution is the best proven technology used by global leading companies in the semiconductor, display, secondary battery and automobile fields.

-

- The new realm of machine vision - the smart factory

- Various applications integrated with INTEKPLUS's vision module technology, which are being applied to high-tech industries, are the optimal solution in the smart factory era.