Secondary Battery

Inspection

-

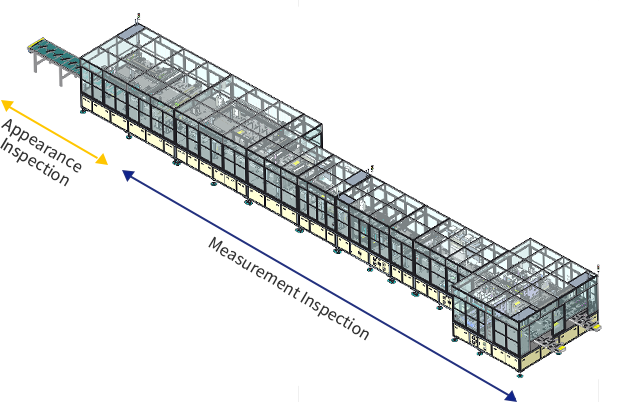

Integrated Measurement System

Visual inspection of secondary

batteries for automobiles -

INTEKPLUS's unique vision machine technology, which has been reknownd in the cutting-edge industrial field, will present the standard for visual inspection of secondary batteries for automobiles.

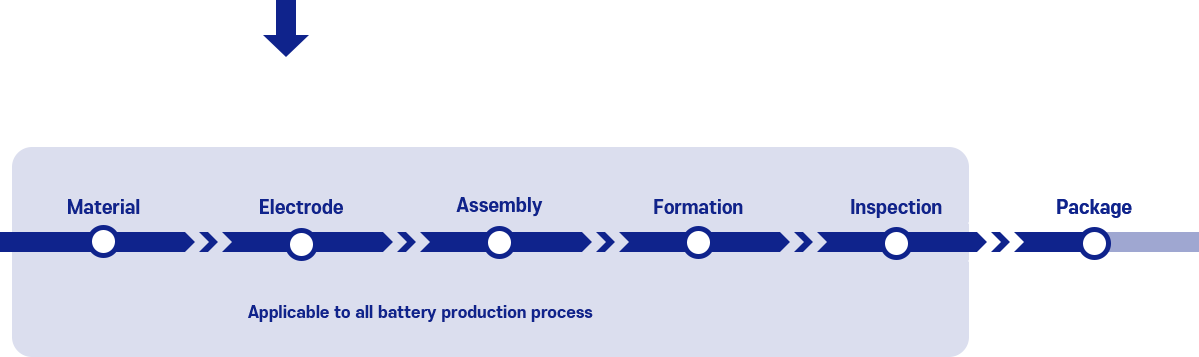

IN SECONDARY BATTERY PRODUCTION

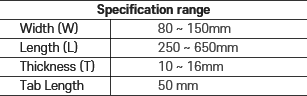

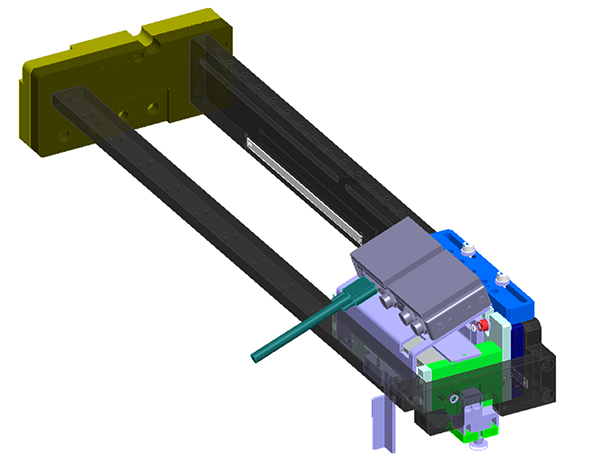

- Secondary Battery Cell Tester

- The secondary battery cell tester is a device that inspects the appearance, dimensions, and electrical characteristics of pouch type battery cells.

-

PPM (Max)

18 ppm (Ave. 16.5 ppm↑)

-

Dimension

Customizing available

iBIM-E200 : W3,300 x D 22,215 x H2,250mm

iBAIS-S200 : W15,500 x D7,500 x H3,400mm

W3,800 x D 21,645 x H2,250mm

-

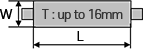

Object

Secondary battery for EV (Pouch type)

-

Model

iBIM-E200

iBAIS-S200

iBIM-C200

“Measurement Inspection Solution to Securing Battery Cell Quality and Safety”

-

- Precision Inspection

- Applied Position Adjustment Program

-

- Tab Inspection

- Optimized Tab Cutting Dimensional Inspection

-

- Inspection Performance

- Applied Vision Technology Optimized for Secondary Battery

-

Thickness

-

IR/OCV

-

Insulation

-

Marking

Unit -

Marking

Reader -

Marking

Verifier -

Tab cutting

-

Tab size

-

Weight

-

NG Sorting

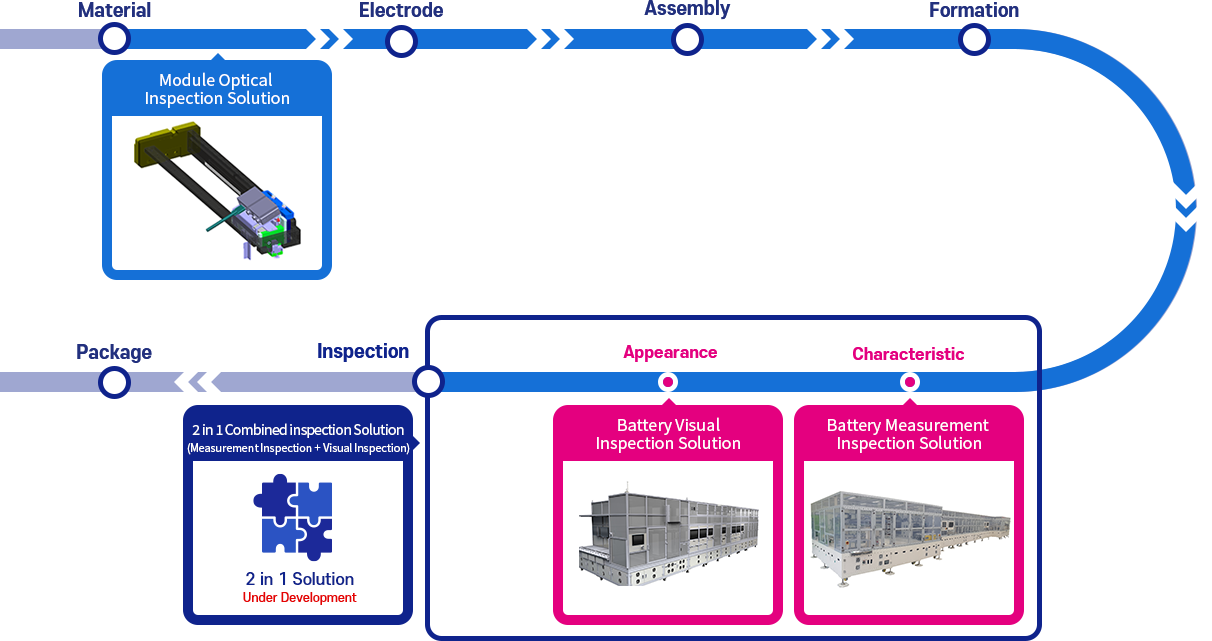

2D & 3D High-tech inspection system with Deep Learning brings you Improvement of Inspection Quality

"Smart & Complete Appearance Inspection for Battery Cell"

-

- Vision inspection

-

3D/2D

Inspection

-

- Deep learning

-

Smart & precise

detection

-

- Convenience

-

User-Friendly

Interface

-

Scratch

-

Pressed

-

Stabbed

-

Folded (Electrode)

-

Folded (Separator)

-

Polluted

(Outer) -

Polluted

(Inner)

-

Scratch

-

Stabbed

-

Folded

(Electrode) -

Polluted

(Outer) -

Burr

-

Pressed

-

Stabbed

-

Incorrect

Folding -

Height

Folding

-

Curved

-

Bulge

-

Stabbed

(Inner) -

Electrode

wrinkle

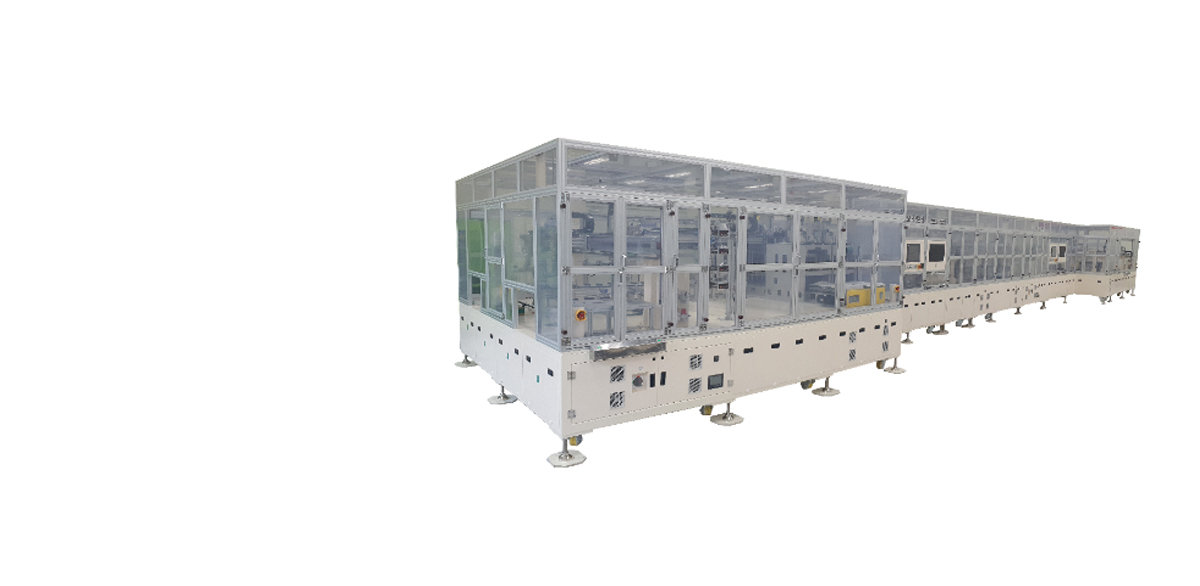

Integrated Inspection Solution which allows Physical & Electrical measurement and Appearance inspection by itself.

-

- Integrated Inspection

-

Measurement

& Appearance Inspection

-

- Vision inspection

- 3D/2D Inspection

-

- Convenience

-

User-Friendly

Interface

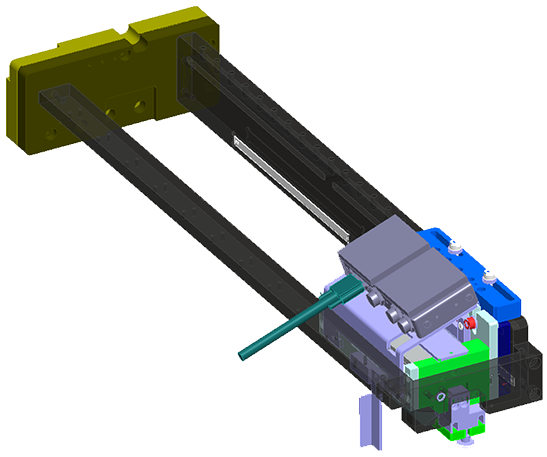

- Secondary battery optical module

- The compact optical module that can be applied to all secondary battery production processes contains the latest technology of INTEKPLUS.

-

PPM (Max)

18 ppm (Ave. 16.5 ppm↑)

-

Dimension

W3,300 x D 22,215 x H2,250mm (Customizing available)

-

Object

Applicable to all battery production process

-

Model

iBMI-M100

-

- Vision Inspection

- 3D/2D Combined Inspection

-

- Space utilization

- Installation of Equipments

-

- Customizing

- Applicable to all Process