Semiconductor

Backend Visual Inspection

-

Integrated Measurement System

Semiconductor Backend

Visual Inspection -

Micro Vision Technology thoroughly inspects the microscopic and complex semiconductor packaging process.

INTEKPLUS's excellent Vision Technology, selected by Global Semiconductor manufacturers, provides the best inspection solution in the Semiconductor backend visual inspection process.

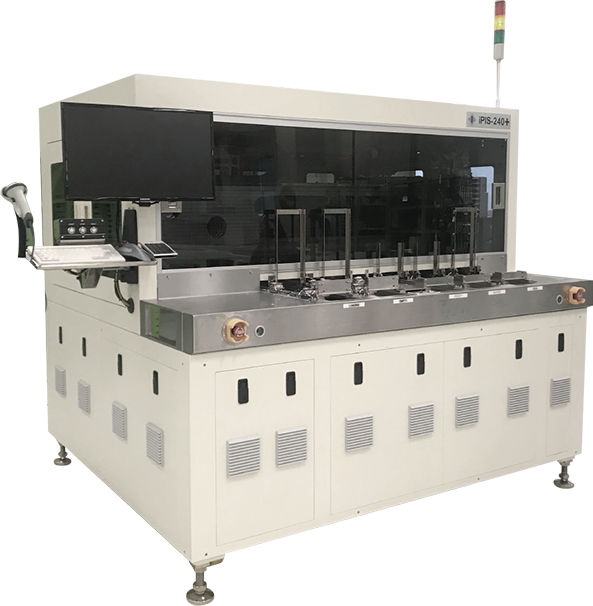

Semiconductor Package Inspection System

-

iPIS-HX Series

-

HIGH DETECTABILITY

HEXA PLATFORM -

Premium Solution of Supporting

6 Sides Inspection (Top/Bottom

2D/3D, 4 Side)High Detectability for Advanced

Package Inspection (SiP, CIS ···)Supports Advanced Inspection

Options: Real Total Height (Top 3D),

Top Side Dent, Side LFF Stitching,

Multi Picker and Deep Learning

Related Model : 140HX, 240HX,340HX -

HIGH DETECTABILITY

-

iPIS-XTR Series

-

EXTENDABILITY

TR PLATFORM -

All-in-one Inspection Solution

with 3 Rail for 6 Side + Tape & ReelCost-effective Upgrades which

enable to extend Equipment

LifecycleMaximized Extension Capability

Selective Inspection Available for

Customer Inspection Needs

(Advanced Package, Side

Inspection)

Related Model : X140TR, X240TR,X340TR -

EXTENDABILITY

-

iPIS-IN Series

-

IN-TRAY PLATFORM

INSTANT INSPECTION -

World Best Productivity Supporting

In-tray Handling method with 5 Rail

Based PlatformMinimize the Handing Damage with

Tray Flipping TechnologyStable Handing with Precise

Stitching for Large PackagesOption: HX Platform, Tape & Reel

Related Model : 380, 560, 580 -

IN-TRAY PLATFORM

- iPIS-HX Series

- Ultra-high-resolution vision solution and precision high-speed Pick & Place handling technology provide high productivity and detectability.

-

Inspection Stage2D Vision

Top / Bottom / 4 Sides

3D VisionTop / Bottom

-

General SpecificationInspection PKG

TSOP/ LDP/ QFP/ BGA/

BOC/ QFN/ usD CARD etc.UPHMax 80K

Package Size2x2mm ~ 120x120mm

-

ExtensionHexa(HX)

-

Related Model

iPIS-140HX

iPIS-240HX

iPIS-340HX

HEXA PLATFORM

140HX, 240HX, 340HX

Premium Solution of Supporting 6 Sides Inspection

(Top/Bottom 2D/3D, 4 Side)

High Detectability for Advanced Package Inspection

(CIS,SiP, Heterogeneous Integration)

Supports Advanced Inspection Options :

Real Total Height (Top 3D), Top Side Dent,

Side LFF Stitching , Multi Picker and Deep Learning

-

Pick & Place

Handling

Method -

UPH

Max 80K -

Top 2/3D

Bottom 2/3D,

4 Side -

Advanced

Package -

Direct View

Mechanism -

LFF Stitching

120x120

-

Real Total

Height -

Deep

Learning -

Multi

Picker

-

- Handling Method

- Pick & Place

-

- UPH

- MAX 70K

-

- Inspection

- Top/Bottom

2D/3D

-

- Package

-

Advanced

Package

-

- LFF

Stitching - 85x85

- LFF

-

- LTSM

- Long-term Stability Monitoring

-

- Extension 1

- 4 Side 2D

-

- Extension 2

- Side LFF

Stitching

-

- Extension 3

- Direct View Mechanism

-

- Feature 1

-

Top 3D

(Real Total Height)

-

- Feature 2

- Deep Learning

-

- Handling Method

- Pick & Place

-

- UPH

- MAX 60K

-

- Inspection

- Top/Bottom

2D/3D

-

- Package

-

Advanced

Package

-

- LFF

Stitching - 80x80

- LFF

-

- LTSM

- Long-term Stability Monitoring

-

- Extension 1

- 4 Side 2D

-

- Extension 2

- Side LFF

Stitching

-

- Extension 3

- Direct View Mechanism

-

- Feature 1

-

Top 3D

(Real Total Height)

-

- Feature 2

- Deep Learning

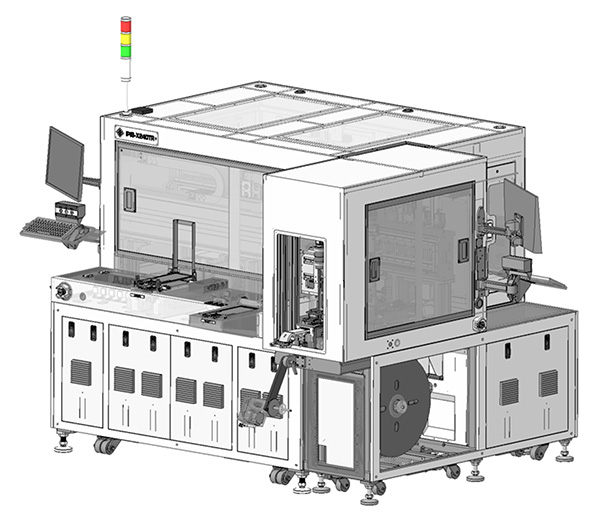

- iPIS-XTR Series

-

iPIS-XTR Series is an All-in-one inspection solution that integrates Machine Vision Inspection System and Conventional Tape & Reel Handler.

Auto Reel Changer enables further extended to achieve Full Automation of the Post Reel Process.

-

Inspection Stage2D Vision

Top / Bottom / 4 Sides

3D VisionTop / Bottom

-

General SpecificationInspection PKG

TSOP/ LDP/ QFP/ BGA/

BOC/ QFN/ usD CARD etc.UPHMax 70K

Package Size -

Extension

Auto Reel Changer(ARC)

-

Related Model

iPIS-X140TR

iPIS-X240TR

iPIS-X340TR

TR PLATFORM

X140TR, X240TR, X340TR

All-in-one Inspection Solution with 3Rail for 6 Side + Tape & Reel

Cost-effective Upgrades which enable to extend Equipment Lifecycle

Maximized Extension Capability

Selective Inspection Available for Customer Inspection

Needs(Advanced Package, Side Inspection)

-

Pick & Place

Handling

Method -

UPH

Max 70K -

Bottom

2/3D,

Top 2D -

Tape &

Reel

Extension -

Direct View

Mechanism -

Vision

Extension

Available

-

Multi Picker

-

Deep

Learning -

Auto Reel

Changer

Auto Reel Changer enables to automate Reel Taping,

Barcode Label Attach and Protection Bander attaching,

which was inevitable by the operator.

-

- Reel Taping

-

- Barcode Label Attach

-

- Label Printer

-

- Dual Reel Changer

-

- Protection Bander

-

- Finished Reel Stacker

- iPIS-IN Series

-

iPIS-IN Series performs visual inspection while the semiconductor package is mounted on the tray.

Our advanced Tray flipping technology materializes fast and accurate inspection without package damage.

-

Inspection Stage2D Vision

Top / Bottom / 4 Sides

Top / Bottom -

General SpecificationInspection PKG

TSOP/ LDP/ QFP/ BGA/

BOC/ QFN/ usD CARD etc.UPHMax 100K

Package Size3×3mm ~ 120×120mm

-

Extension

Hexa(HX) / Tape & Reel (TR)

Auto Reel Changer(ARC)

-

Related Model

iPIS-380

iPIS-560

iPIS-580

INSTANT INSPECTION

380, 560, 580

World Best Productivity Supporting In-tray Handling method with 5 Rail Based Platform

Minimize the Handling Damage with Tray Flipping Technology

Stable Handling with Precise Stitching for Large Packages

Option: HX Platform, TR

-

In-tray

Handling

Method -

UPH

Max 100K -

Bottom

2/3D,

Top 2/3D -

2D/3D LFF

Stitching -

Tray

Flipping

Technology -

Auto

Sorting

System

-

HX

Platfom -

Tape &

Reel -

Side LFF

Stitching -

Deep

Learning

-

- Handling Method

- In-tray

-

- UPH

- MAX 85K

-

- Inspection

- Top/Bottom

2D/3D

-

- LFF

-

2D/3D

Stitching

-

- Damage

- Damage

Free

-

- Sorting

- Auto System

-

- Extension 1

- 4 Side 2D

-

- Extension 2

- Side LFF

Stitching

-

- Feature 1

- Deep Learning

-

- Feature 2

- Tape & Reel

-

- Handling Method

- In-tray

-

- UPH

- MAX 100K

-

- Inspection

- Top/Bottom

2D/3D

-

- LFF

-

2D/3D

Stitching

-

- Damage

- Damage

Free

-

- Sorting

- Auto System

-

- Extension 1

- 4 Side 2D

-

- Extension 2

- Side LFF

Stitching

-

- Feature 1

- Deep Learning

-

- Feature 2

- Tape & Reel

- Memory Module/SSD AVI

-

INTEKPLUS's Memory Module FVI Inspection platform inspects the visual defects of memory modules.

Real-time 3D inspection through optical triangulation provides inspection of products of various sizes.

-

Memory ModuleSSD AVI

-

Inspection StageiMAS-2000

DIMM, SODIMM, FBDIMM

iSSD-Q1000D2.5” SATA, mSATA, RAID LIF, Gumstick1, Gumstick2

-

General Specification

Top/Bottom 2D&3D

Top/Bottom 2D&3D

Side 2D -

Extension

2,000 EA

(@SODIMM)6,000 EA

(@ 2.5” CASE) -

Model

- iMAS-2000

- iSSD-Q1000D

-

- UPH

- Max.2000

-

- In-out

- Direct Tray In-out

-

- Review

- Reject Review Station

-

- Sorting

- Auto Sorting

-

- Light System

- 3Band Light System

-

- Job Teaching

- Fast Job Teaching

-

- UPH

- Max.6000

-

- Inspection

- 5Para Single

Head Inspection

-

- Review

- Reject Review

Station

-

- In-out

- Direct Tray

In-out

-

- Auto Conversion

- Jig Auto Conversion for Inspection

-

- Sorting Picker

- Sorting Picker

-

- Light

- 3Band Light System

-

- Job Teaching

- Fast Job Teaching

-

- Sorting

- Auto Sorting